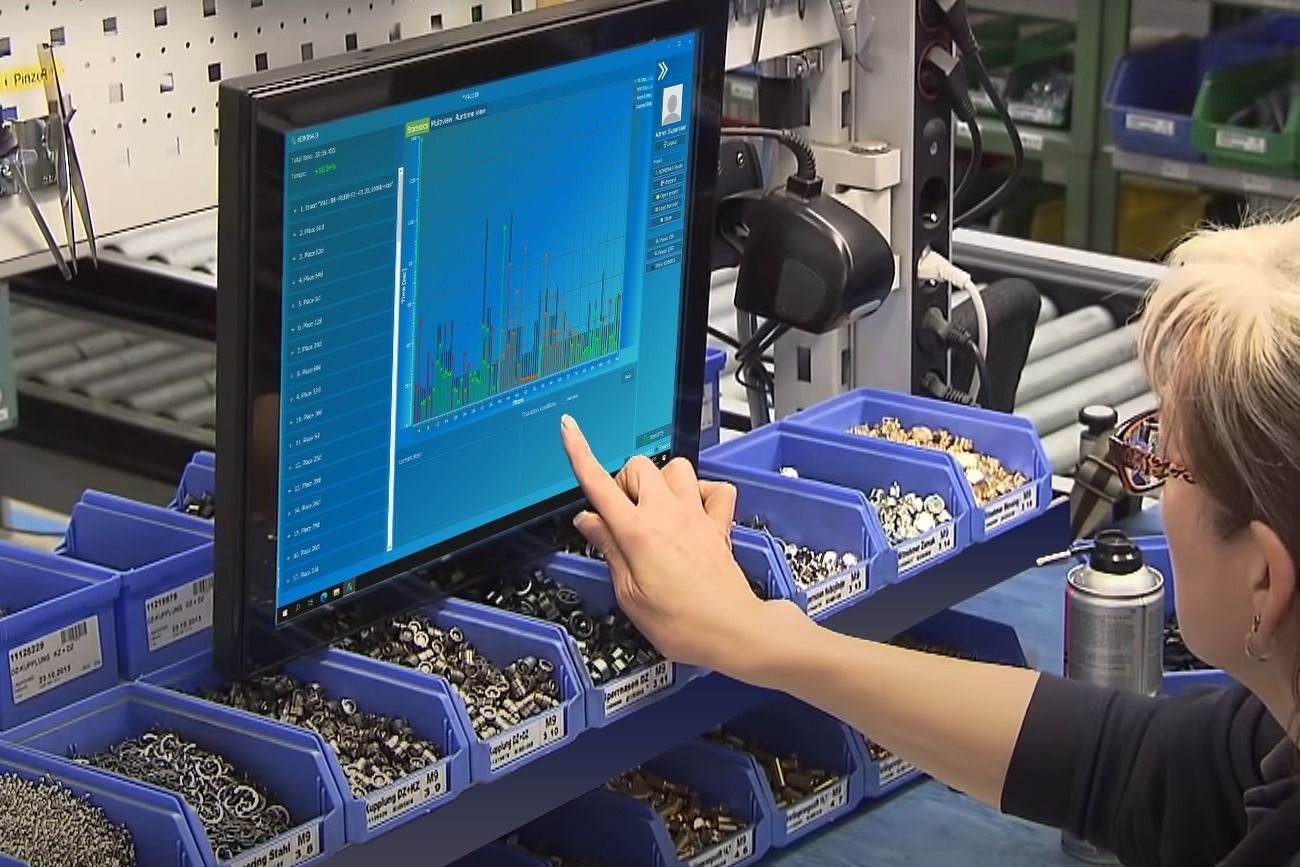

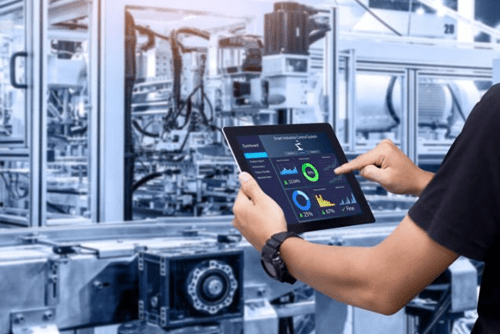

Innovation of the manufactory in your own hands

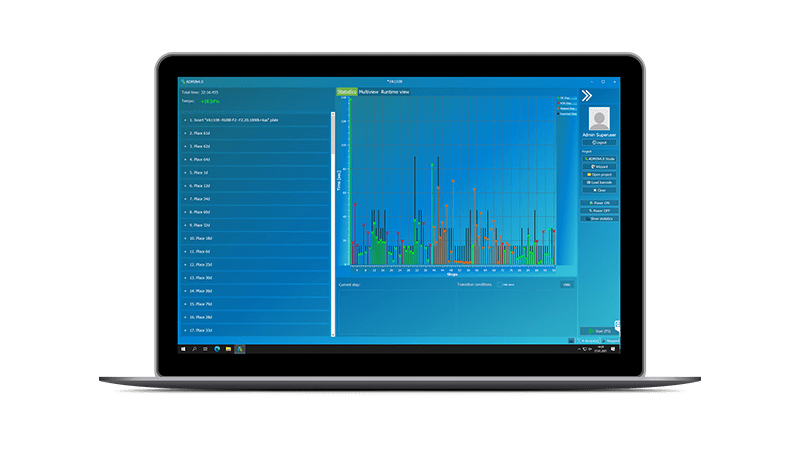

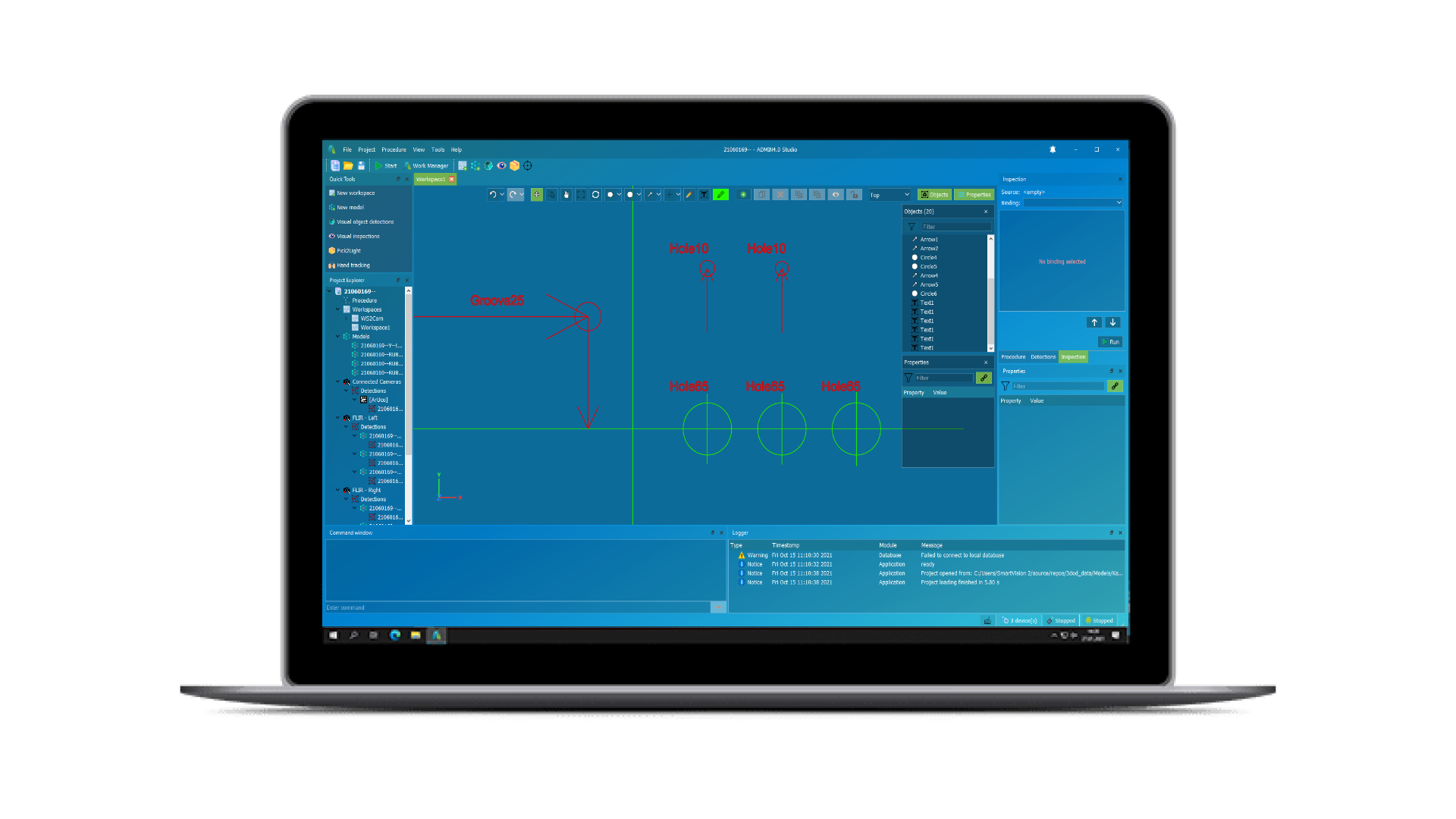

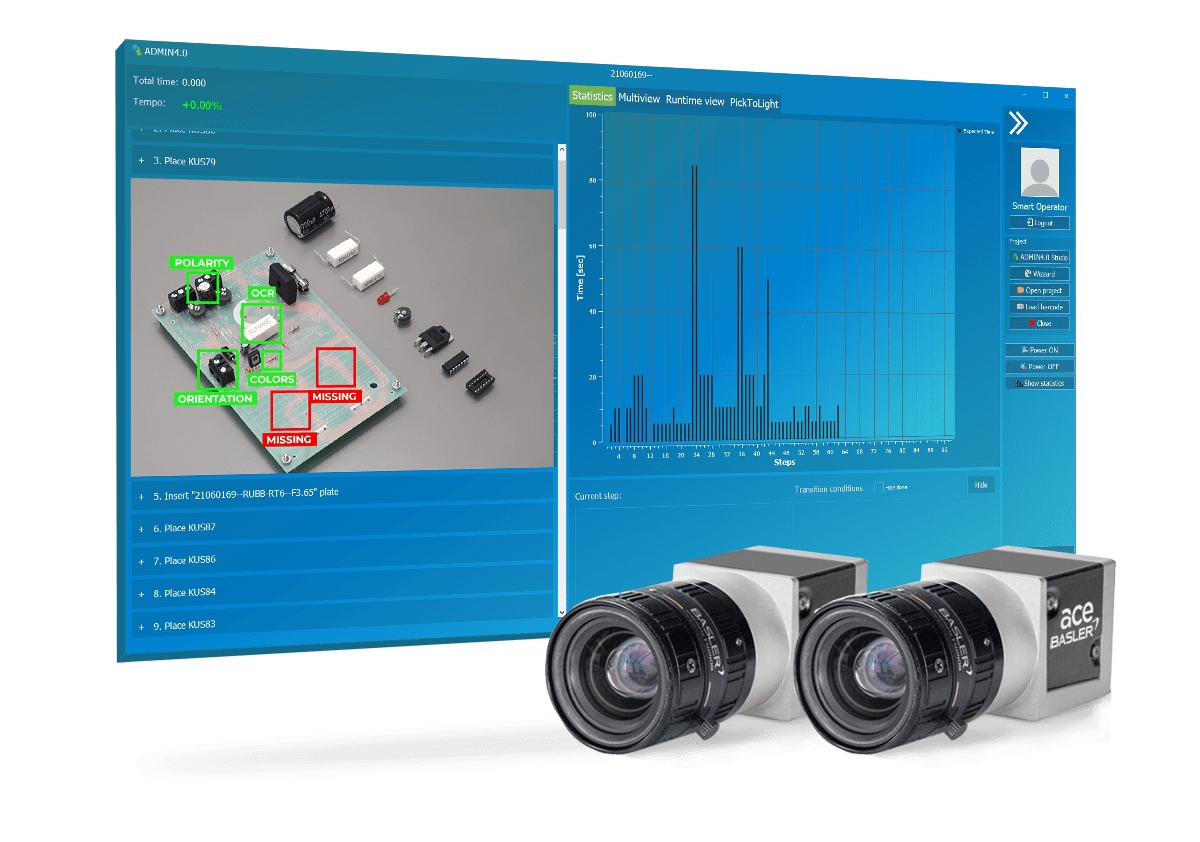

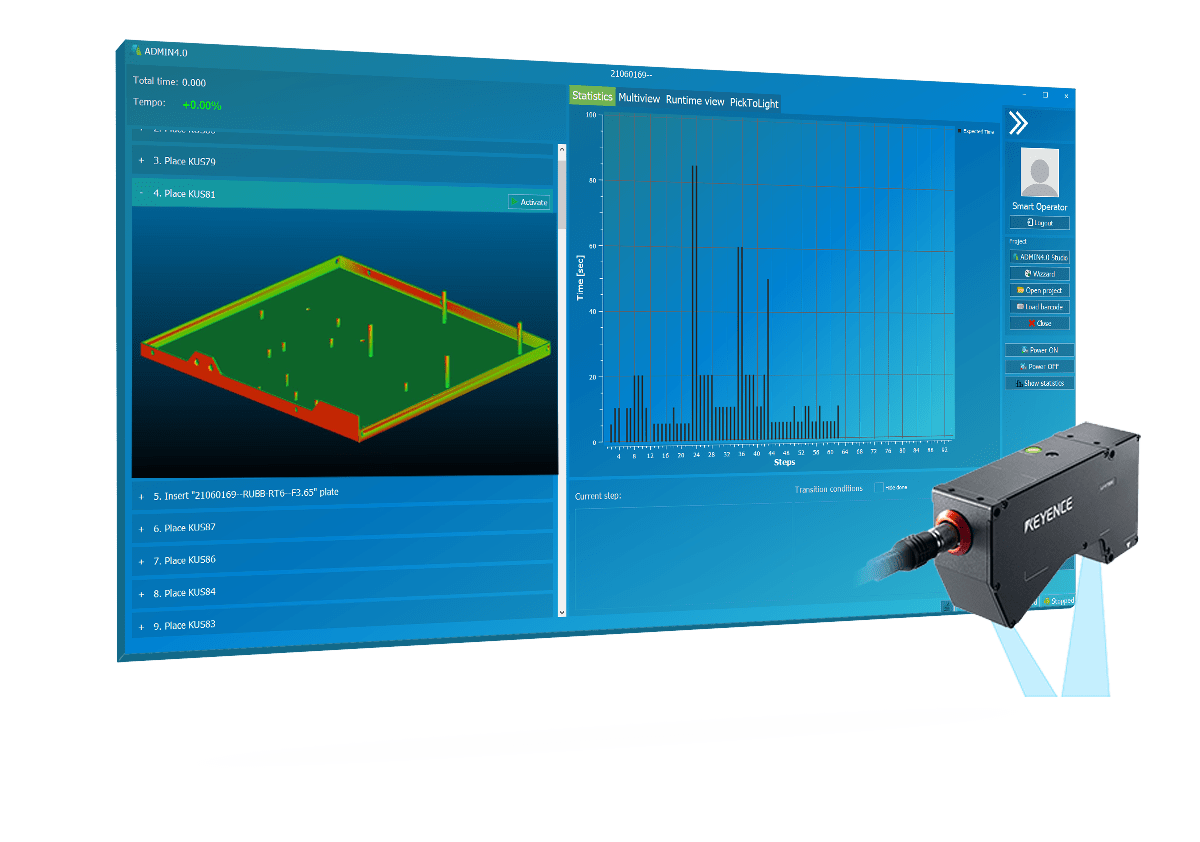

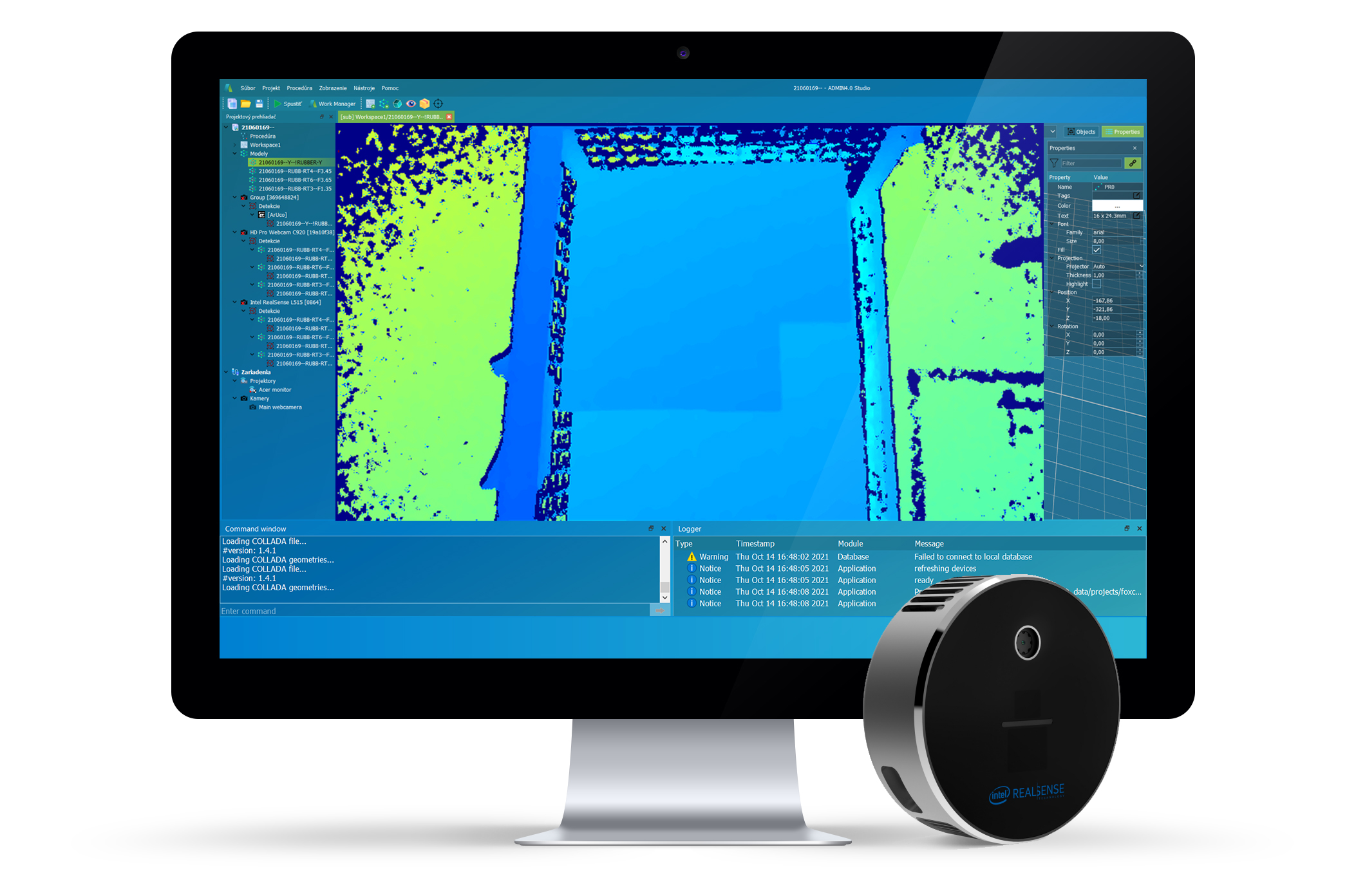

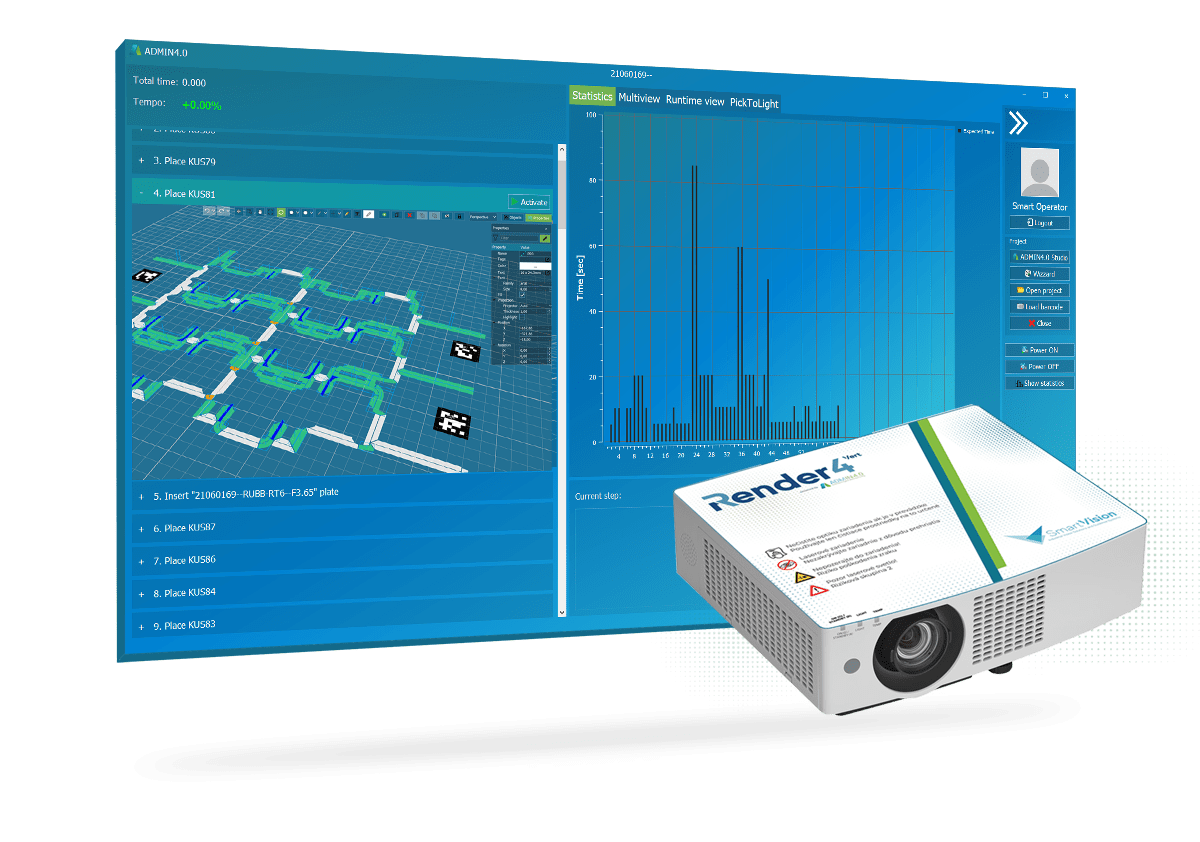

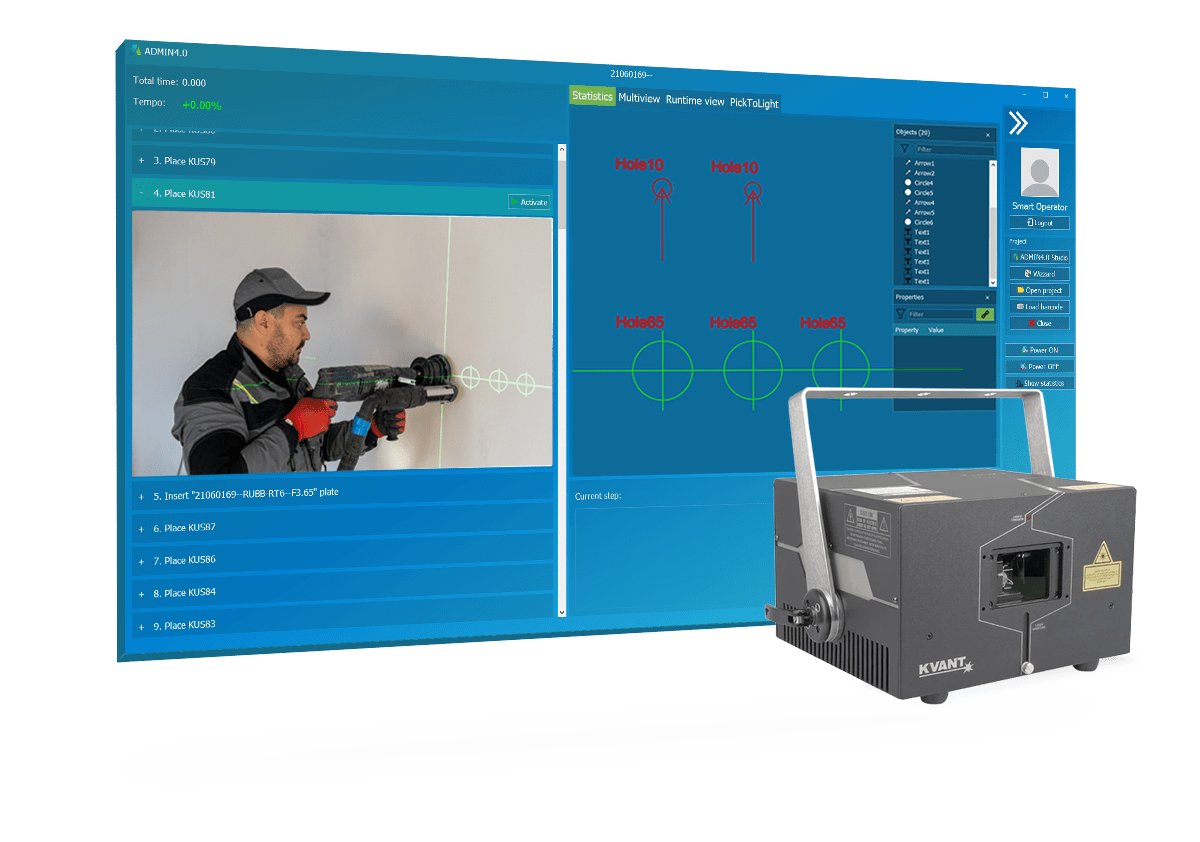

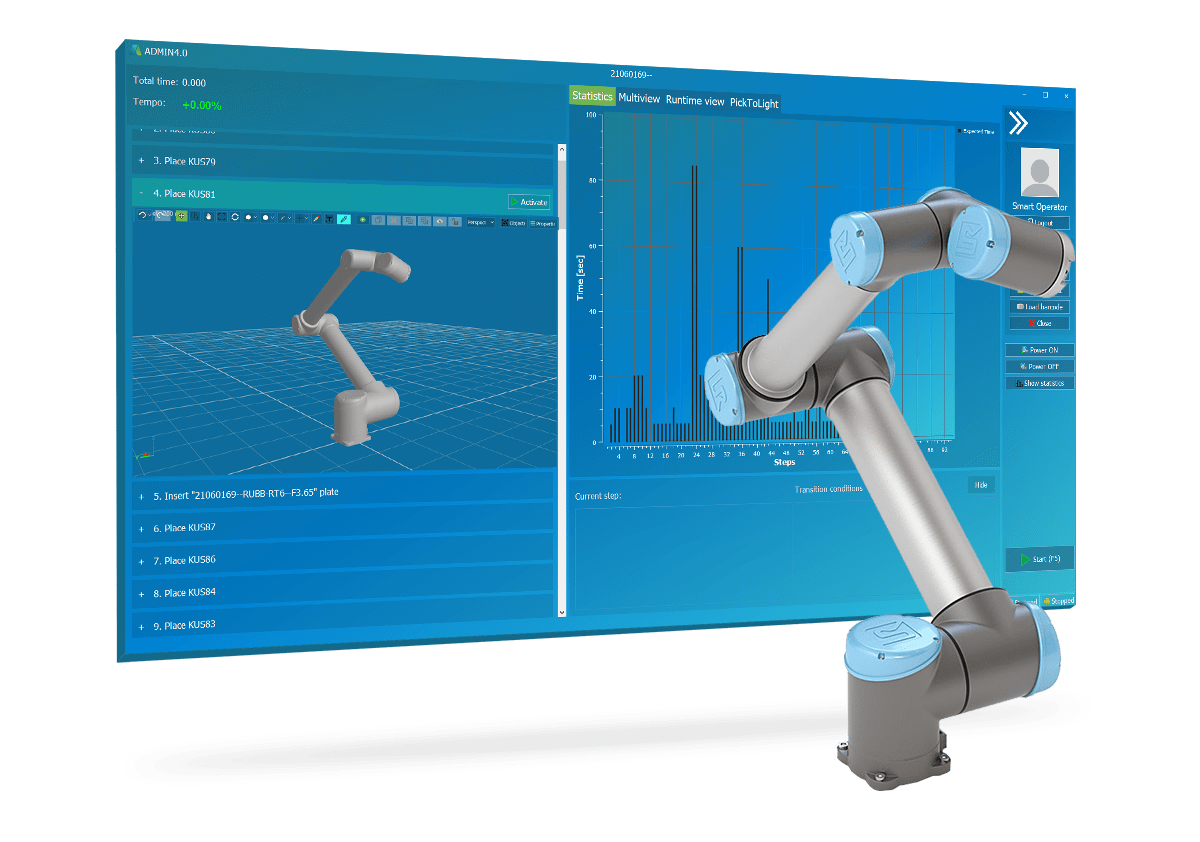

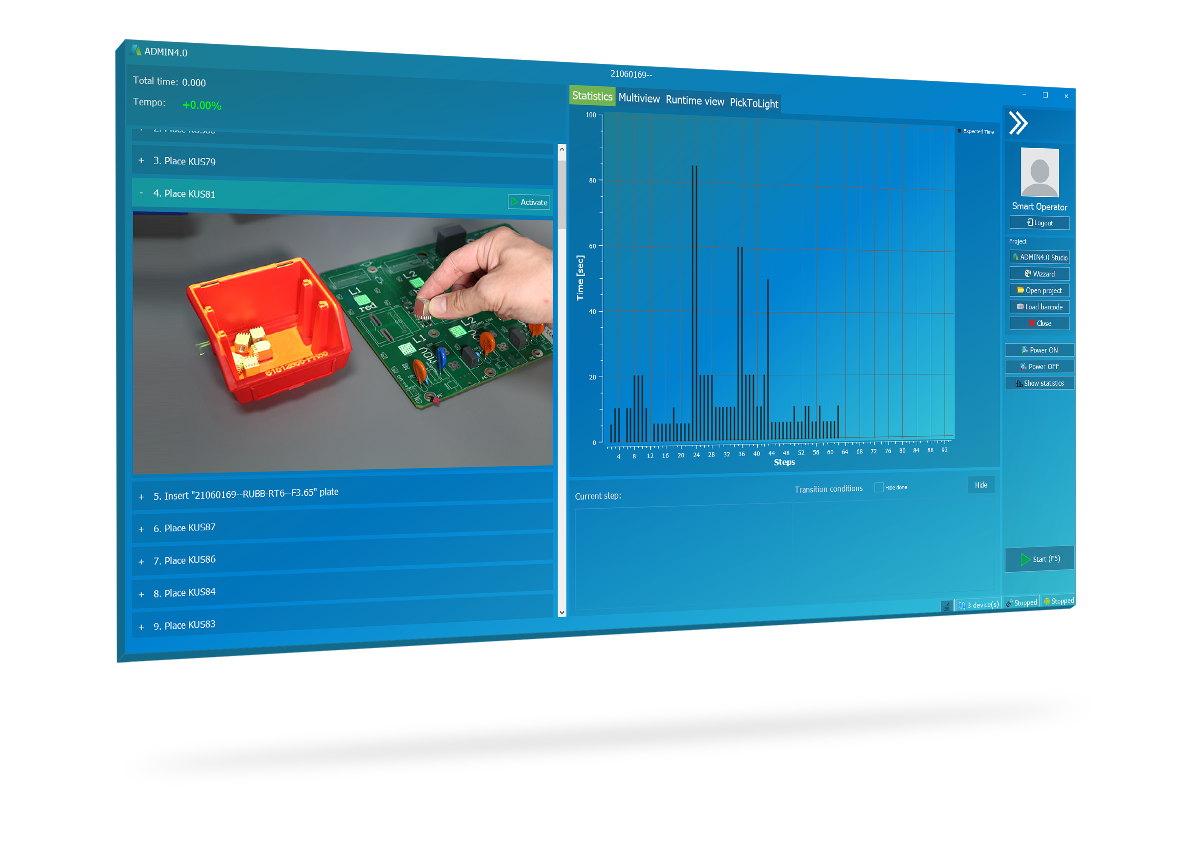

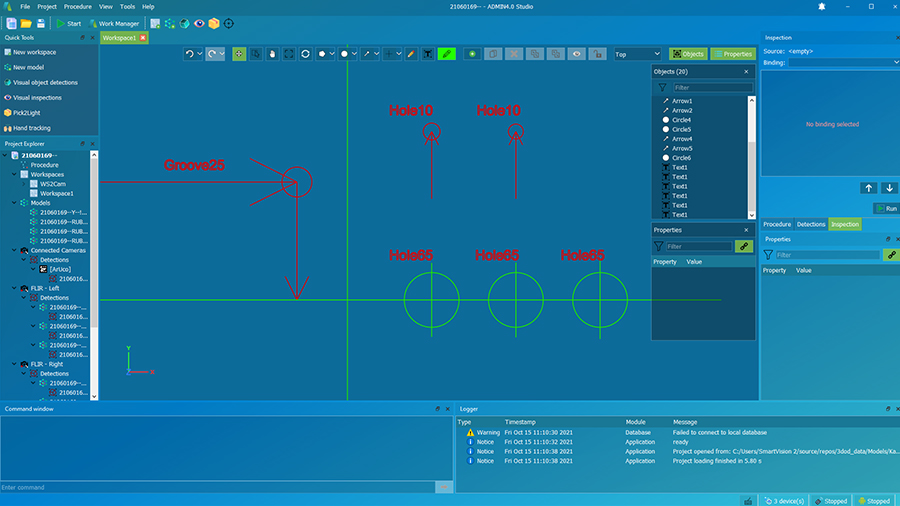

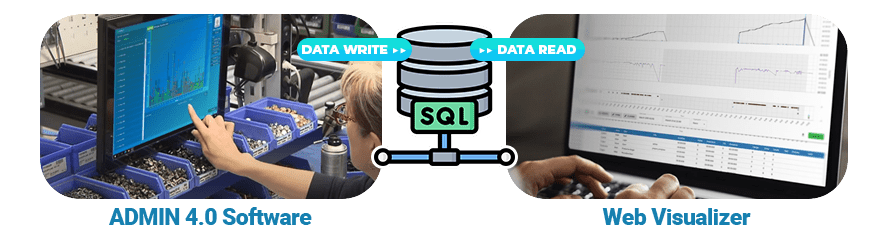

Smart Vision, a company from Slovakia, has taken a different path and developed a system for cooperative operator guidance and quality control, which uniquely supports manufactory production instead of automation by machines. Increasing efficiency and reducing work errors means directly linking the worker to the computer so that the system not only guides but also controls the work performed. At the same time, it makes sure that it does not restrict the worker, thus naturally creating man-machine cooperation.