Visual guidance and quality control in the manufactory

Open up endless possibilities for digitizing your workplace with the ADMIN4.0 visual guidance and control system.

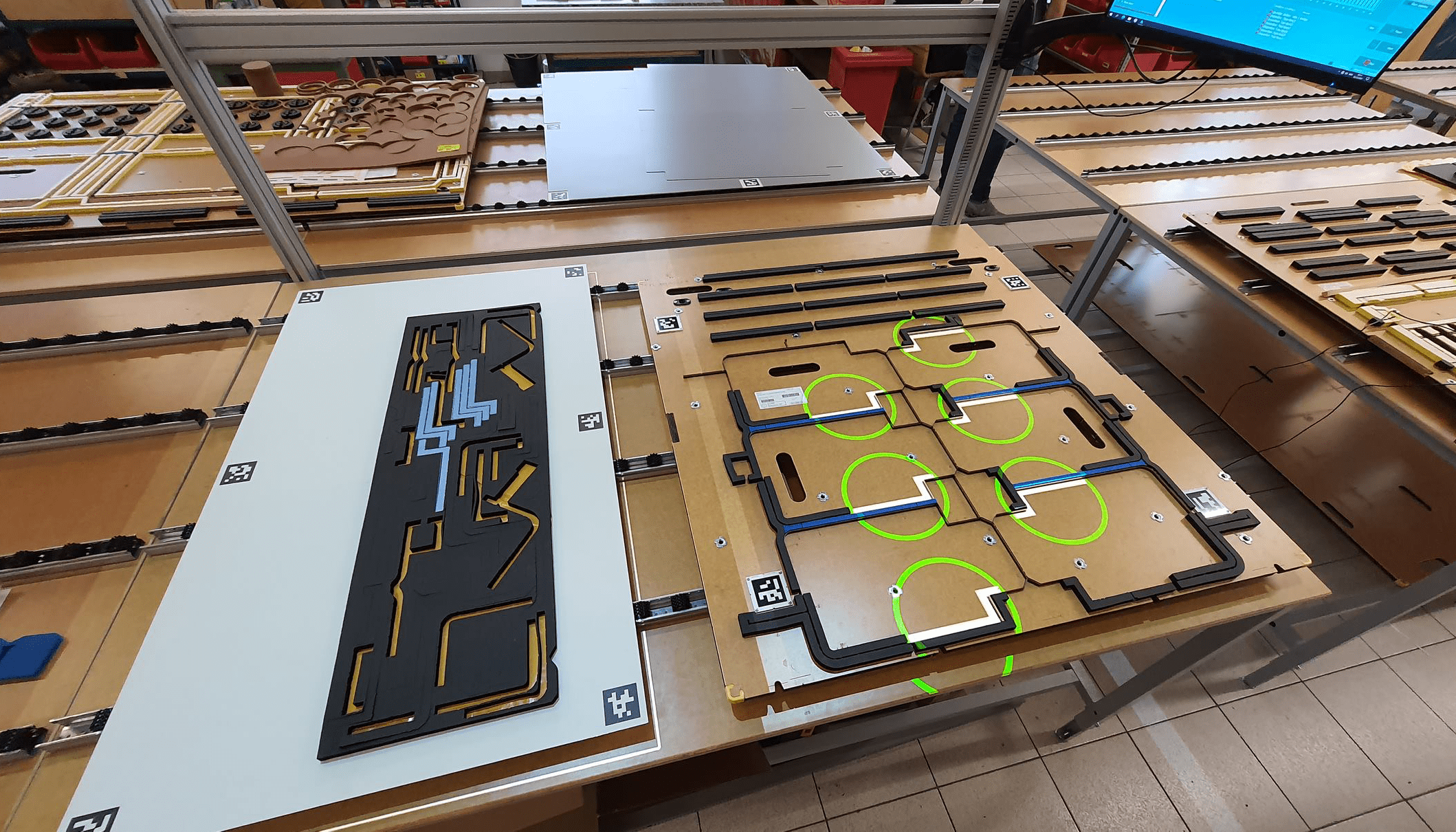

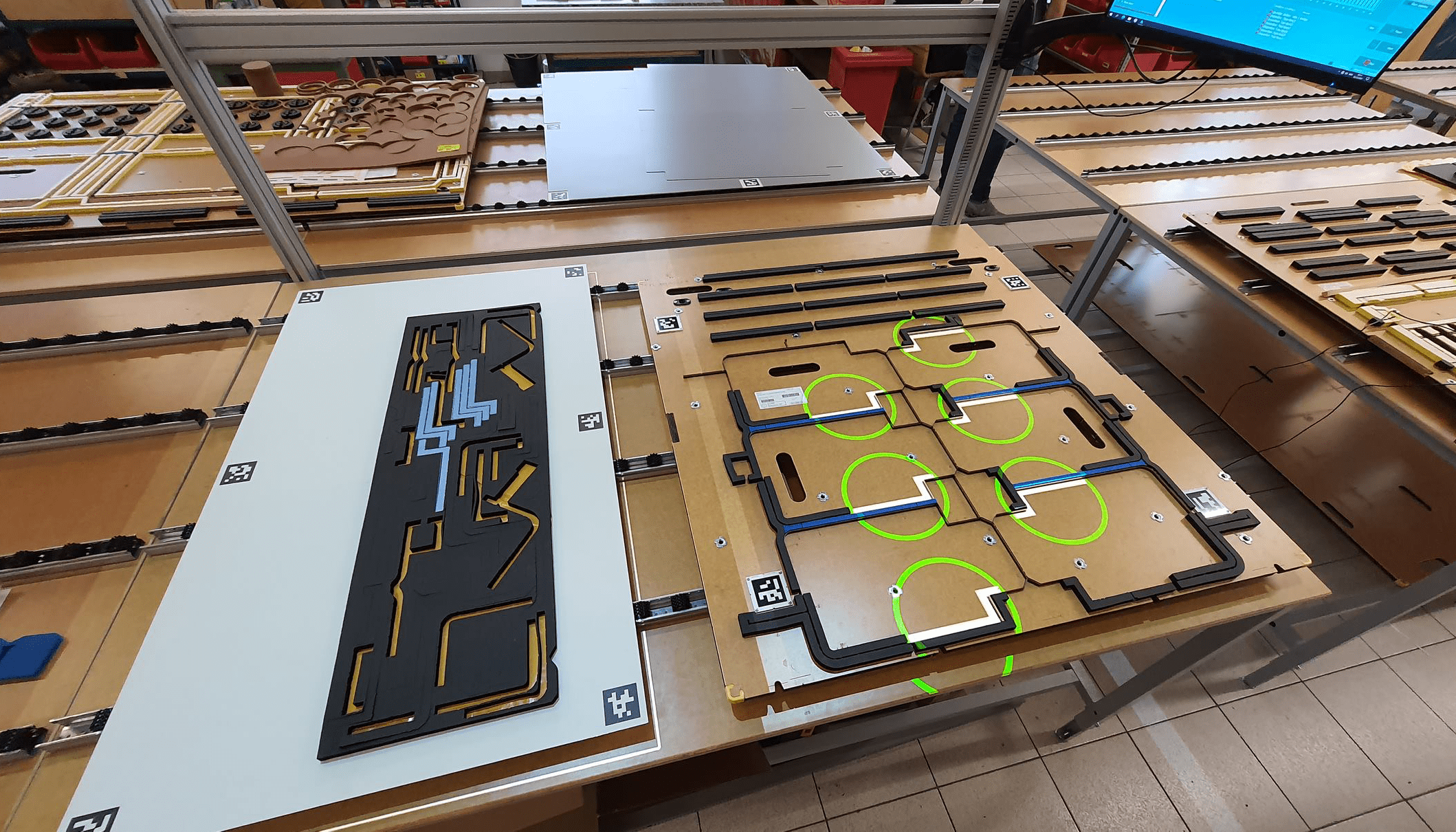

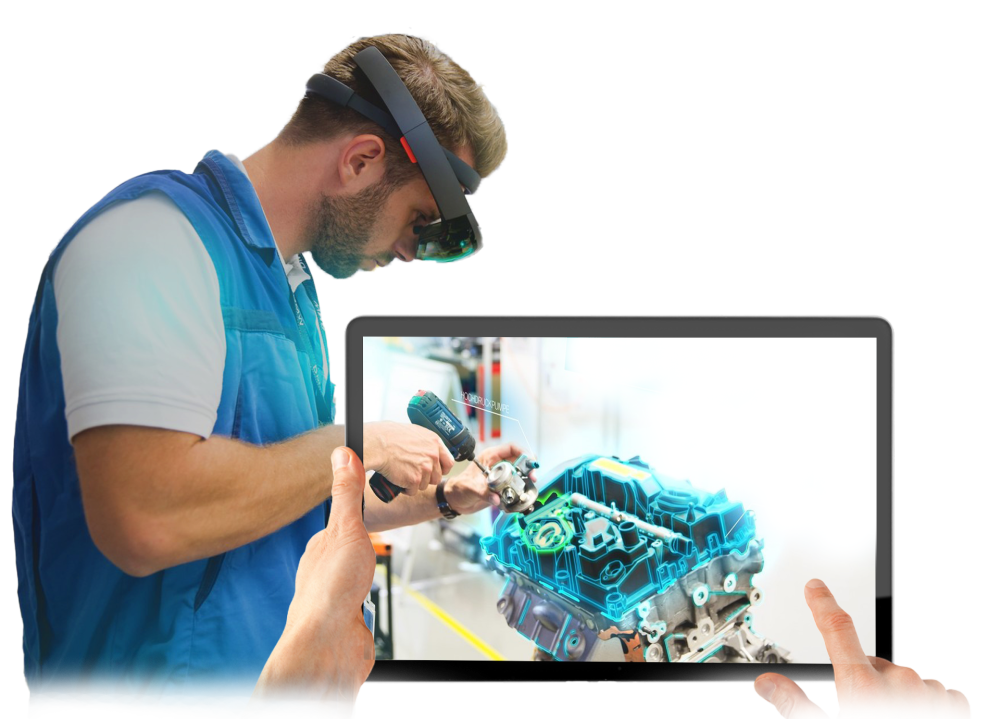

AR visual guidance

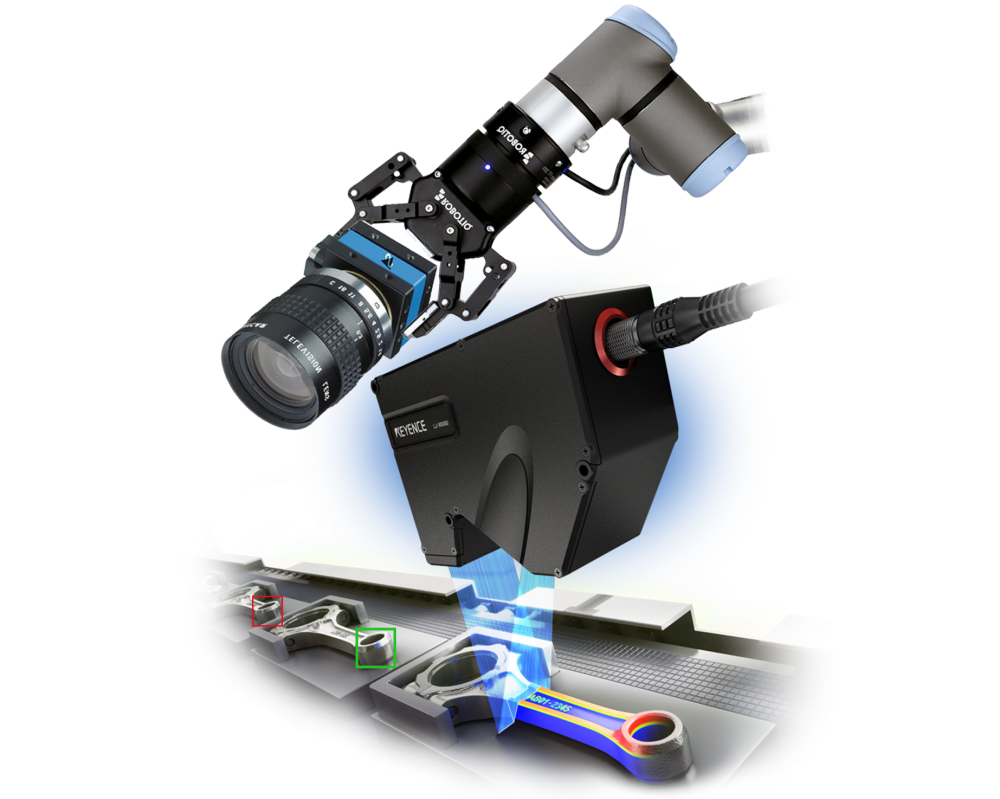

AI camera control

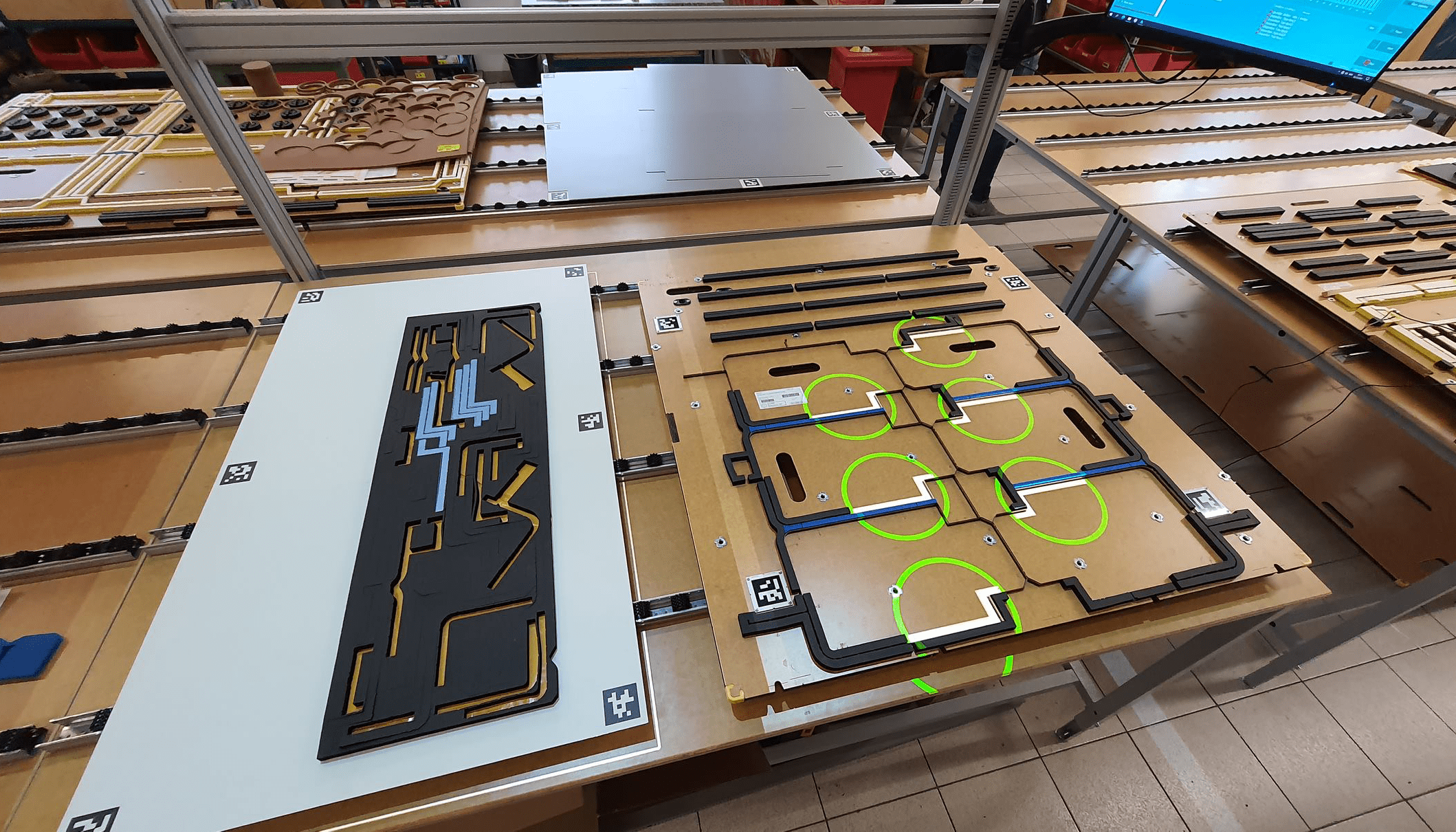

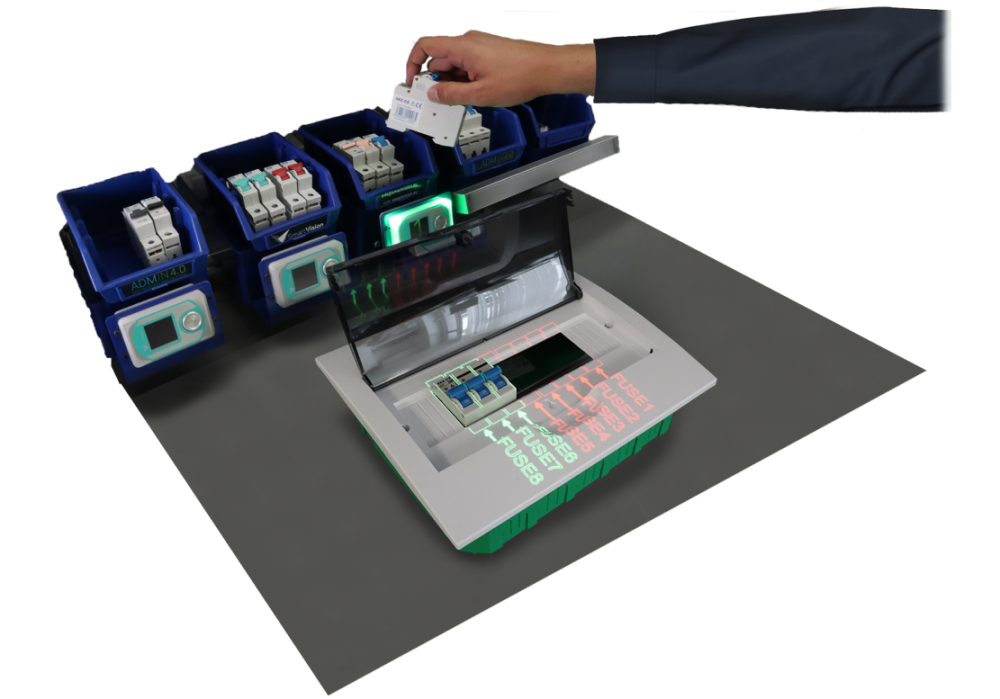

Material management Pick to Light

Process digitization

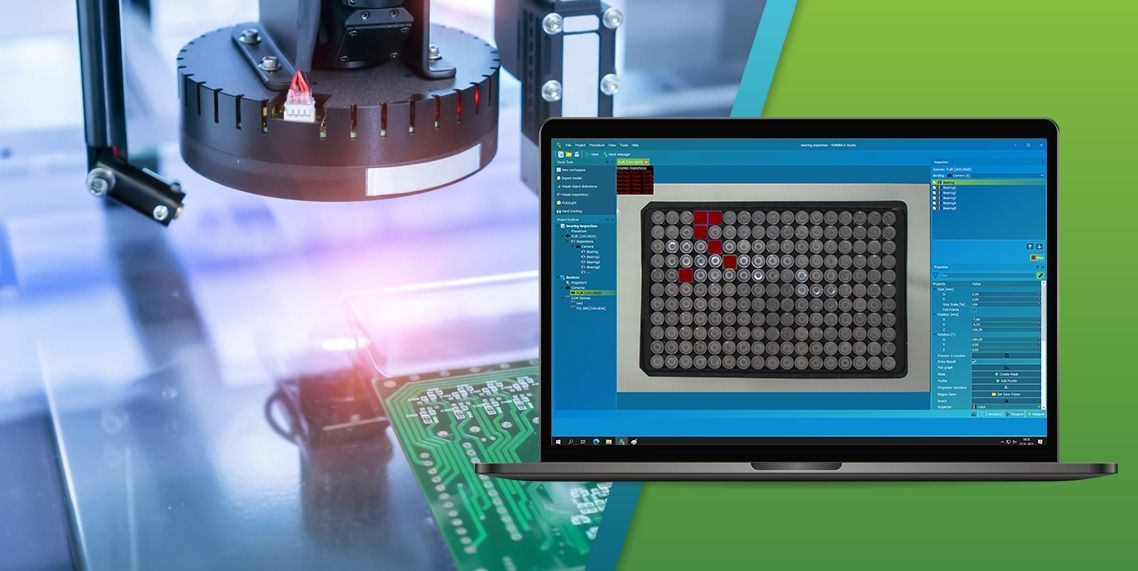

Quality inspection using artificial intelligence

Artificial intelligence provides a wide range of quality control options and allows you to solve challenging tasks simply.

Presence control

Inspection for correctness

Recognition of defects

Object position detection

Augmented reality and mobile quality control

Tablet as a tool for visual guidance and quality control in your hand. A flexible system that can be used in any workplace.

Assisted mounting

Mobile quality control

Operator briefing

Assisted Digital Manufacturing System in Industry4.0

Assisted digital manufacturing in Industry 4.0 is a software platform that provides unlimited configuration options for digitizing your workplace and processes.

Artificial intelligence

Mixed reality

Robotics

Material management

Data processing

Visual guidance and quality control in the manufactory

Open up endless possibilities for digitizing your workplace with the ADMIN4.0 visual guidance and control system.

AR visual guidance

AI camera control

Material management Pick to Light

Process digitization

Quality inspection using artificial intelligence

Artificial intelligence provides a wide range of quality control options and allows you to solve challenging tasks simply.

Presence control

Inspection for correctness

Recognition of defects

Object position detection

Augmented reality and mobile quality control

Tablet as a tool for visual guidance and quality control in your hand. A flexible system that can be used in any workplace.

Assisted mounting

Mobile quality control

Operator briefing

Assisted Digital Manufacturing System in Industry4.0

Assisted digital manufacturing in Industry 4.0 is a software platform that provides unlimited configuration options for digitizing your workplace and processes.

Artificial intelligence

Mixed reality

Robotics

Material management

Data processing

Assisted Digital Manufacturing System in Industry4.0

The ADMIN4.0 platform allows you to create advanced processes by linking visual and control functions into a single unit using only configuration, without programming knowledge. It is a powerful tool that combines multiple technologies and communicates them to the user in a simple way. All you need to do is to choose…

Assisted Digital Manufacturing System in Industry4.0

The ADMIN4.0 platform allows you to create advanced processes by linking visual and control functions into a single unit using only configuration, without programming knowledge. It is a powerful tool that combines multiple technologies and communicates them to the user in a simple way. All you need to do is to choose…

One tool for all solutions

Everything you need for your project can be created with a single ADMIN4.0 tool.

One tool for all solutions

Everything you need for your project can be created with a single ADMIN4.0 tool.

We simplify and digitise industrial manufacturing

Take a look at the benefits of the collaborative manufactory created by our ADMIN4.0 system:

We simplify and digitise industrial manufacturing

Take a look at the benefits of the collaborative manufactory created by our ADMIN4.0 system:

ADMIN4.0 can be the solution for you too. Innovate the approach – keep the work.

6 years of innovation in SmartVision

Our story is being written by a number of interesting and innovative projects. Check them out.

6 years of innovation in SmartVision

Our story is being written by a number of interesting and innovative projects. Check them out.

News

Our consultant

for implementation in your production

Lukáš Richter – process improvement consultant

I specialize in increasing the productivity of companies, LEAN management and continuous improvement KAIZEN. My clients are companies, regardless of industry, who are not reconciled to the inefficiency of their processes.

In 14 years of practice, I have helped more than 150 companies become better. Each has its own story, its own journey. But the common thread has been a drive to move people and improve the way the company operates.

Our clients

Industrial sectors