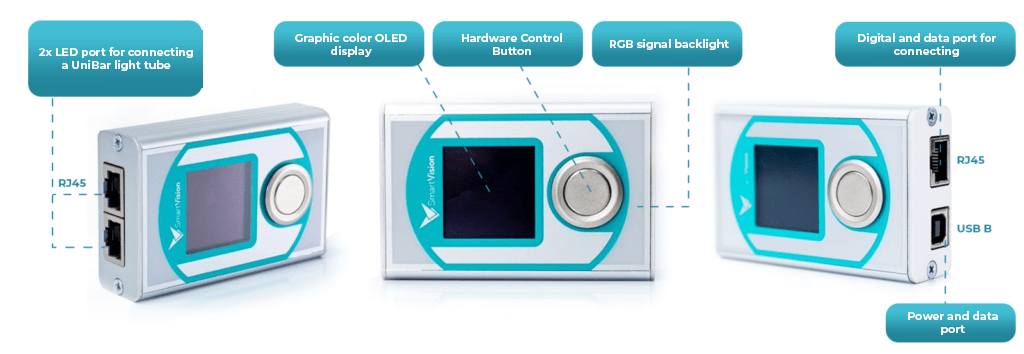

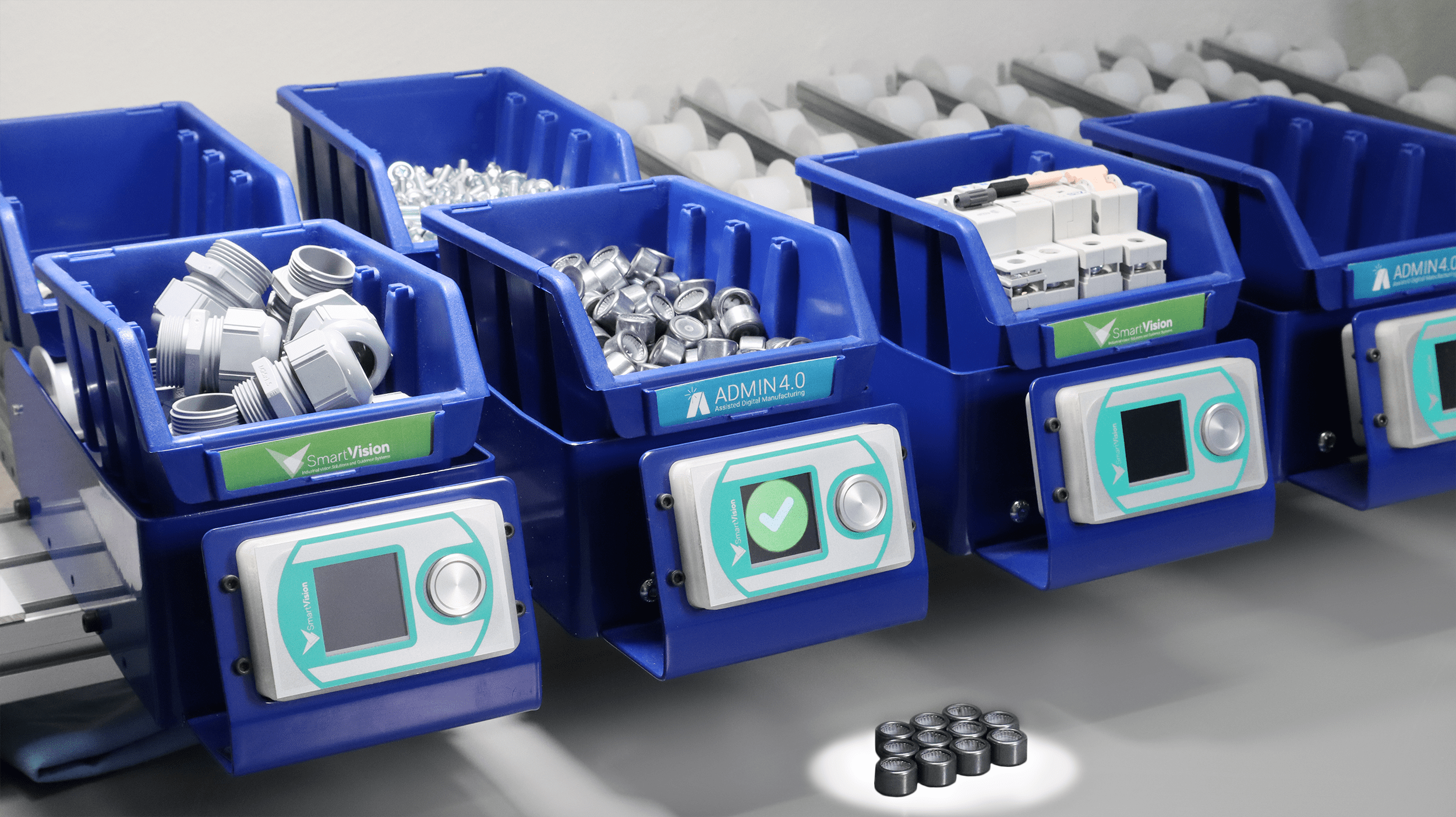

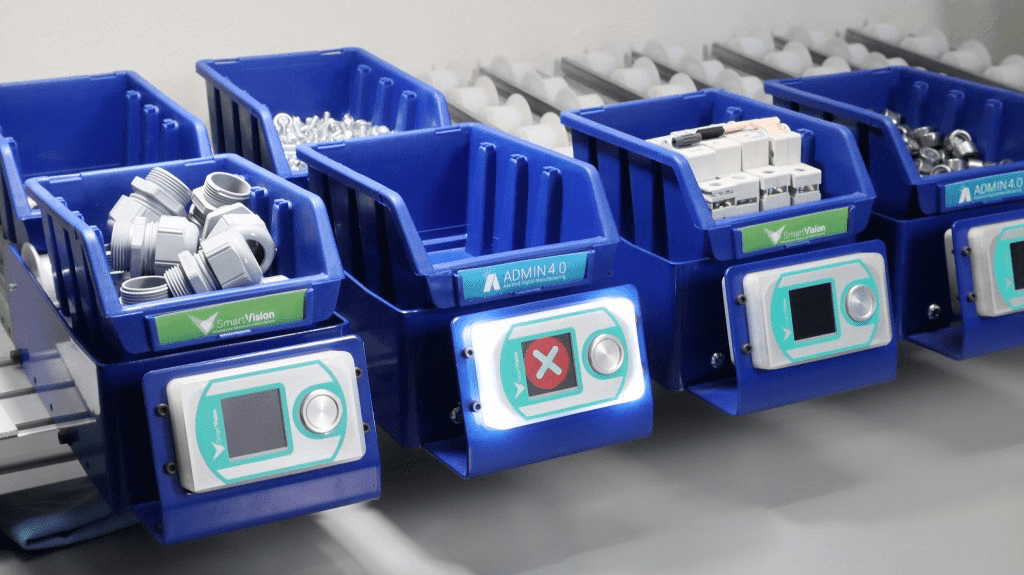

UniBox is a universal multifunctional module for controlling material picking by light signals. The UniBox module provides graphical visualisation via OLED display, connection of various peripherals such as a component weighing counter and intelligent control configuration in conjunction with ADMIN4.0 for your warehouse or assembly workstations.

Unique material flow control system

Signalling and graphic display

LED backlight signalling and information graphics on the colour OLED display provide the operator with clear instructions when working with goods and materials. The ability to display custom information graphics allows the equipment to be closely linked to production operations.

Wireless connection

Wireless connectivity for mobile applications such as supply trolleys or flexible warehouse positions. It can be connected to the corporate network or to a local station using 2.4/5GHz.

UniBar Addressed Light Array

UniBox allows the connection of up to two UniBar LED light tubes with a total length of 8 meters, which can cover the entire workplace, supply trolley or warehouse rack with addressed light signals. UniBar devices connect via an RJ45 connector, which is also ready for wiring custom solutions using a 3-wire LED strip.

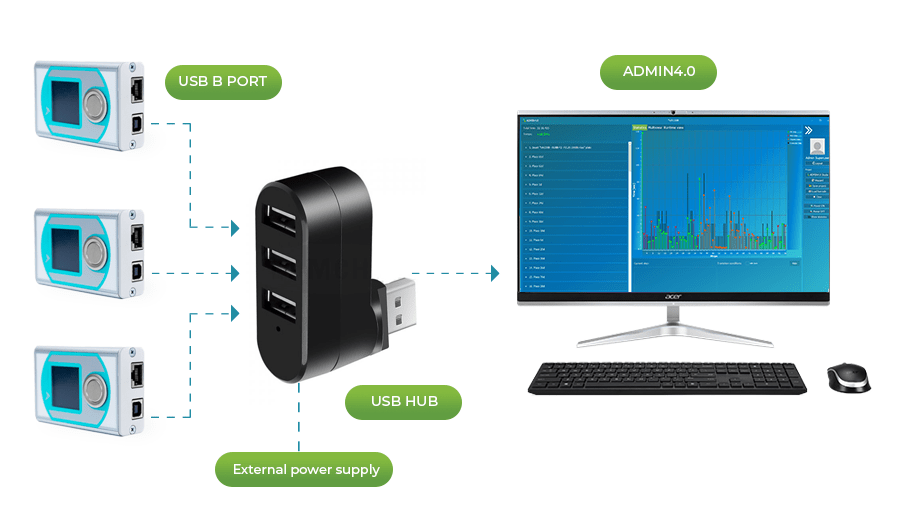

Power and data connection

The USB B connector serves as a data connection to a PC running ADMIN4.0 and also as a 5VDC / 0.5A power supply. Using a USB hub with its own power supply, an unlimited number of devices can be connected to a single USB bus of the PC.

Connecting UniIO peripherals

The I/O port allows connection and communication with external devices using the I2C bus, or the 5VDC digital inputs and outputs. The port allows you to connect the following:

UniCounter weighing counter

Material control module for installation into custom station designs. Weighing modules are optional with a range from 1 to 10kg and 1g accuracy. Connection to UniBox module via I2C bus. Using the weighing module, the system can alert the warehouse in time for material replenishment to the workstation.

UniDock platform

Pick to Light station for controlled access to material on the workplace, allowing you to control the amount of material using a weighing counter built into the platform and a replenishment rail for continuous material flow.

UniRack supply trolley

Linking the workplace and the warehouse with a light-controlled supply trolley helps to alert the warehouse in time for incoming material and replenish it with a supply trolley that communicates directly with the workstation and allows light-pairing of the replenishment positions on it.

Controlled material flow in the workplace

Technical specification

Device | UniBox GUIDE | UniBox SMART | Counter |

Max. power consumption [W] | 2,5 | 10 | 0,1 |

Input voltage [VDC] | 5 | 5 | 5 |

Max. input current* [A] | 0,5 | 2 | 0,02 |

Output voltage [VDC] | 5 | 5 | - |

Max. output current** [A] | 0,4 | 1,5 | - |

Operating temperature [°C] | -25 to +50 | -25 to +50 | -25 to +50 |

Storage temperature [°C] | -40 to +60 | -40 to +60 | -40 to +60 |

IP protection | IP 43 | IP 43 | IP 67 |

Comparison

Unibox Guide

UniCounter

I2C

Unibox Smart

UniCounter

UniBar

Digital I/O

I2C

Uni Features